Case Study: WD-40 Specialist® Gel Lube and Dry Lube Take Flight with Space Manufacturer

Case Study: WD-40 Specialist® Gel Lube and Dry Lube Take Flight with Space Manufacturer

<< BackSpace exploration has long been one of mankind’s most ambitious, challenging, and fascinating pursuits.

An American aerospace manufacturer not only builds spacecraft but also provides space transportation and satellite communications. This corporation is known for its ambitious goals of reducing space transportation costs and enabling the colonization of Mars. In fact, this company has been at the forefront of space innovation, pushing the boundaries of what is possible in space exploration and commercial space activities.

This aerospace manufacturer has a location in MacGregor, Texas. The MacGregor location is used for research and development of new rocket engines and thrusters. They also test final products, components, and engines during development.

WD-40 Team Invited to “Safety Day”

LineDrive was hosting Safety Day for their manufacturing facility and employees. They invited the WD-40 team to participate. This opportunity gave the WD-40 team an opportunity to demonstrate the WD-40 Specialist® products for the maintenance crew, crane operators, and technicians.

The Problem

This spacecraft manufacturer uses crane cables to move heavy engines, thrusters, and other heavy equipment. Moving this heavy equipment puts tremendous force on the crane cables.

Keeping crane cables well lubricated is crucial for maintaining their integrity, ensuring safe operations, and extending their lifespan. Regular lubrication is a fundamental aspect of crane maintenance in all industries where heavy lifting and equipment movement are routine.

7 Ways Lubricant Helps Crane Cables:

Here are seven ways that industrial strength lubricant helps the performance of crane cables.

- Reducing Friction: Lubrication helps to reduce friction between the cable strands and the sheaves or pulleys over which the cables pass.

- Preventing Wear and Abrasion: Heavy equipment movements can put significant stress on crane cables. Without proper lubrication, the strands of the cables can rub against each other, causing wear and abrasion.

- Extending Cable Lifespan: Regular lubrication helps extend the lifespan of crane cables.

- Enhancing Safety: Lubricated cables contribute to the safe operation of cranes.

- Minimizing Corrosion: Cables exposed to environmental conditions, such as moisture or harsh weather, can be prone to corrosion. Lubrication creates a protective barrier that helps prevent corrosion.

- Improving Efficiency: Well-lubricated cables operate more efficiently. They experience less resistance during movement, requiring less energy to lift and lower heavy loads. This efficiency not only saves energy but also contributes to smoother and more precise crane operations.

- Reducing Maintenance Downtime: Regular lubrication reduces the need for maintenance and repairs, minimizing downtime for the crane.

This space company had been using Wet Spray Lubricant on their crane cables. The problem with this product is that it would run and drip.

WD-40 Specialist Products Take Flight

After demoing several WD-40 Specialist products, the aerospace manufacturing company’s team was impressed by the variety of professional-grade products offered by the WD-40 company.

In particular, WD-40 Specialist Dry Lube made an impression on the electricians, who will utilize it for bits and blades.

WD-40 Specialist Gel Lube impressed the crane operators, who will use it on crane cables.

Saving Production Time & Improving Machine Performance

The space exploration company’s crane operators discovered that WD-40 Specialist Gel Lube:

- Goes on thick and stays in place

- Ideal for vertical surfaces, like cables

Though the end users did not mention this additional core benefit, it’s worth noting that WD-40 Specialist® Gel Lube also provides corrosion protection.

The company has the potential to save $10,000 to $15,000 a year just by switching to WD-40 Specialist® Gel Lube.

In summary, after trying WD-40 products for a few weeks, the space manufacturer ultimately decided that WD-40 Specialist products:

- Save production time

- Improve machine performance

With WD-40 Specialist Dry Lube and WD-40 Specialist Gel Lube, work productivity has greatly improved for the space company.

A Closer Look at WD-40 Specialist Gel Lube

WD-40 Specialist Gel Lube, a no-drip formula, offers long lasting lubrication and protection. It is designed also for superior protection that resists water and displaces moisture to prevent rust for up to one year.* This lubricant goes on thick and stays where you spray, making it ideal for use on vertical surfaces and offers non-fling for moving parts such as gears, bearings, cables, chains, rollers and more. Safe to use on multiple surfaces including metals, plastic and rubber.

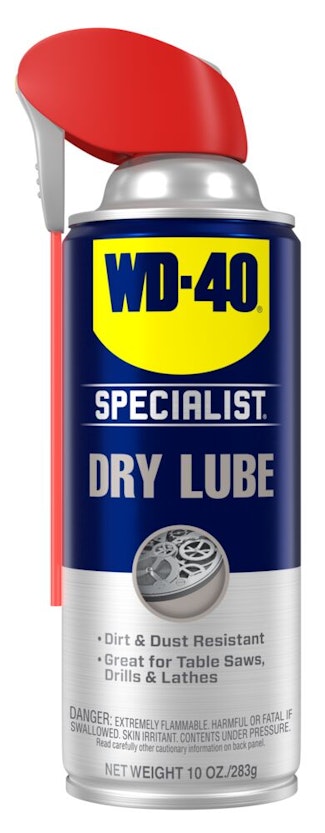

A Closer Look at WD-40 Specialist Dry Lube

WD-40 Specialist Dry Lube keeps your equipment running smoothly with long-lasting corrosion protection without attracting dirt, dust, or oily residue. The dry lube formula is best used where cleanliness and maximum performance are required as it dries quick leaving behind a lubricating film that resists dirt, dust and oil buildups. It is great for reducing friction and wear on blades and bits, door and window tracks, slides, conveyor belts, rollers, hinges, table saws, lathes, power tools and equipment.

Takeaways

The collaboration between the American space manufacturer and WD-40 Specialist products has proven to be a game-changer in enhancing the efficiency and safety of their operations.

Recognizing the unique challenges posed by the heavy equipment and crane cables used in their MacGregor, Texas location, the space company turned to WD-40 Specialist Gel Lube. This high-performance lubricant demonstrated impressive benefits, addressing issues associated with previous products, such as running and dripping.

Applying WD-40 Specialist Gel Lube showcased its ability to stay in place, making it ideal for vertical surfaces like cables, while also offering non-fling characteristics for moving parts. The positive impact on production time and machine performance was evident, with potential cost savings ranging from $10,000 to $15,000 annually.

The switch to WD-40 Specialist products, including Dry Lube for electricians and Gel Lube for crane operators, has not only improved work productivity but also highlighted the versatility and effectiveness of these specialized lubricants in the challenging field of aerospace manufacturing.

Learn more about how to get the job done right, with WD-40 Specialist products.

FEATURED PRODUCTS

WANT TO GET MORE TIPS AND TRICKS?

SUBSCRIBE TO THE NEWSLETTER